About Border Weaving

The double Jacquard weaving process enables us to weave an area of flat fabric to be inserted into the face and/or hem of the towel as an integral part of the construction. Into this flat woven border and/ or hem we can faithfully weave complicated designs, messages and/or corporate logos.

Material: 100% Cotton | Single Cable Yarn | From 360gsm to 600gsm | Reactive Yarn Dyeing

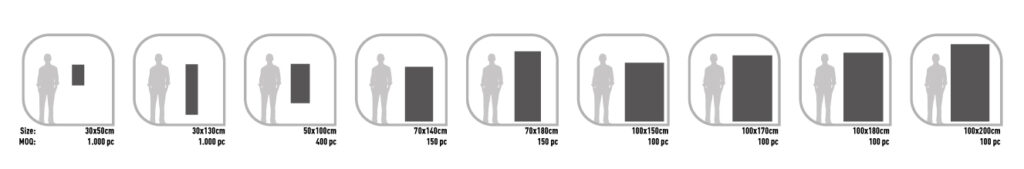

Available sizes and MOQ:

Production

The towel production process may vary depending on the type of towel being produced and the company that manufactures it. However, in general, the process can involve the following steps:

- Design: This step involves creating the towel design, including selecting the size, shape, colors, patterns, and decorative elements.

- Weaving: The towel fabric is woven on a machine, usually using cotton or other textile fibers.

- Dyeing: The towel may be dyed in a single color or multiple colors, depending on the design.

- Cutting: The fabric is cut into pieces according to the size and shape of the towel.

- Finishing: The towel is finished with borders and trimmings, such as hems, fringes, or other decorative elements.

- Quality Inspection: After the towel is completed, it is inspected to ensure that it meets quality standards.

- Packaging and Shipping: The towels are packed and shipped to stores, customers, or warehouses.

Some companies may have more complex processes, with additional steps such as embroidery, printing, or special finishes. Additionally, some companies may have a more sustainable production process, using eco-friendly or recycled materials, or adopting environmentally conscious production practices.

Border Weaving

About Border Weaving

The double Jacquard weaving process enables us to weave an area of flat fabric to be inserted into the face and/or hem of the towel as an integral part of the construction. Into this flat woven border and/ or hem we can faithfully weave omplicated designs, messages and/or corporate logos.

Material: 100% Cotton | Single Cable Yarn | From 360gsm to 600gsm | Reactive Yarn Dyeing

Available sizes and MOQ:

Production

The towel production process may vary depending on the type of towel being produced and the company that manufactures it. However, in general, the process can involve the following steps:

- Design: This step involves creating the towel design, including selecting the size, shape, colors, patterns, and decorative elements.

- Weaving: The towel fabric is woven on a machine, usually using cotton or other textile fibers.

- Dyeing: The towel may be dyed in a single color or multiple colors, depending on the design.

- Cutting: The fabric is cut into pieces according to the size and shape of the towel.

- Finishing: The towel is finished with borders and trimmings, such as hems, fringes, or other decorative elements.

- Quality Inspection: After the towel is completed, it is inspected to ensure that it meets quality standards.

- Packaging and Shipping: The towels are packed and shipped to stores, customers, or warehouses.

Some companies may have more complex processes, with additional steps such as embroidery, printing, or special finishes. Additionally, some companies may have a more sustainable production process, using eco-friendly or recycled materials, or adopting environmentally conscious production practices.